Product Description

Peerless Pumps C825A Pump Bronze fitted

Part #: C825A-5HP

Pump Specifications

- GPM: 150

- RPM: 1767

- H-ft: 58.3

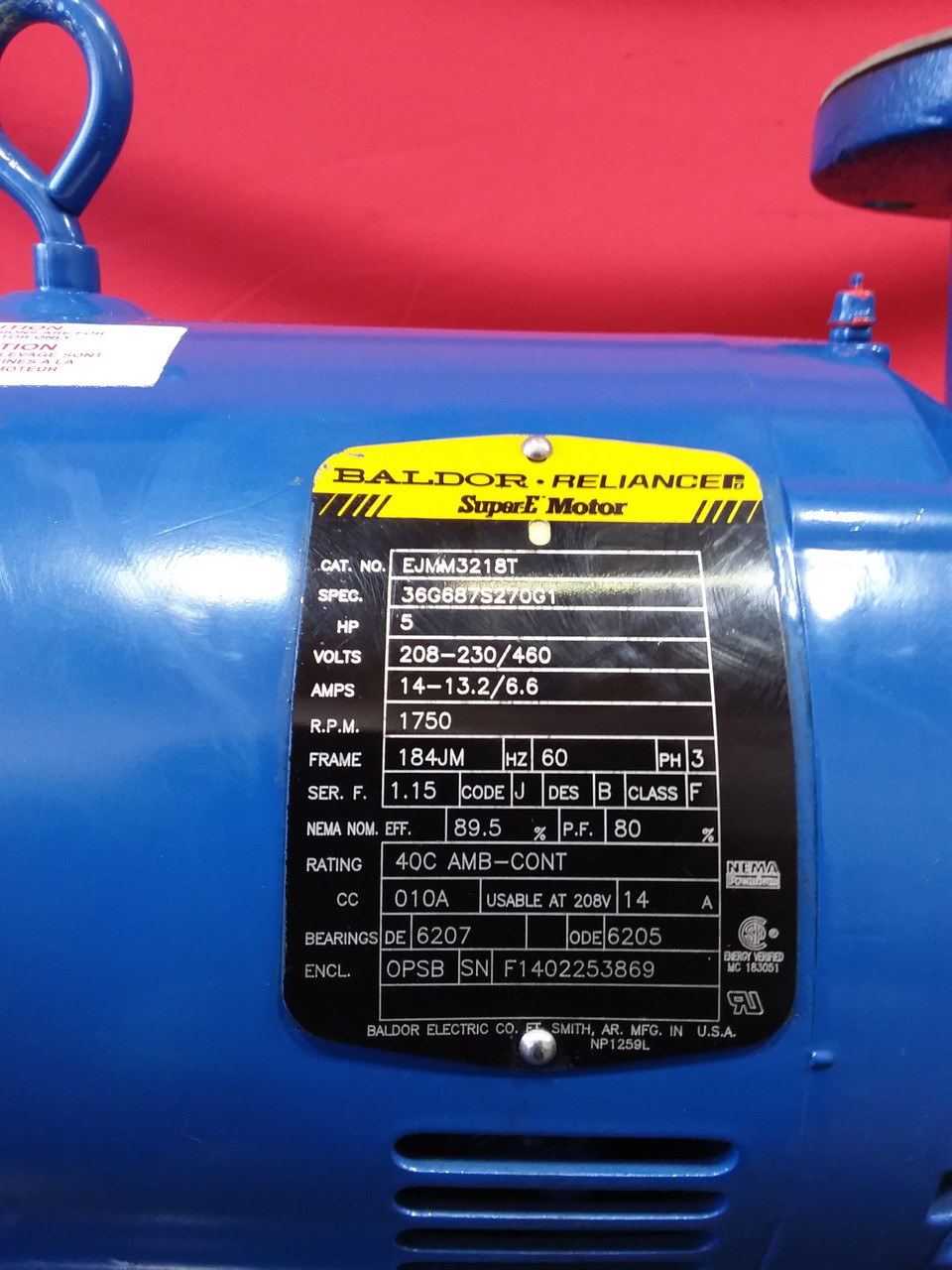

Motor Info

- Baldor EJMM3218T

- HP: 5 HP

- Volts: 208-230/460

- RPM: 1750

Product Description

Peerless General Purpose End Suction Pump.

All pumps come with BALDOR TEFC PREMIUM EFFICIENCY motors.

The Peerless Pump C Series Pumps are close coupled with standard C-face JM or JP solid shaft ball bearing motors specifically designed for pump applications in accordance with standards developed by the Hydraulic Institute (HI) and the National Electrical Manufacturers Association (NEMA).

Applications

Peerless Pump Series C close coupled single suction pumps are designed for applications in medium duty service and provide maximum pump value in heating, air conditioning, booster and general circulating service.

Features

Series C Pumps are available in cast iron bronze fitted and all iron construction. Packed boxes or mechanical seals are available. Pump casing is fitted with a bronze/steel replaceable wear ring. The pipe connection flanges are equivalent 125# ANSI flanges rated for 175# Maximum Working Pressure (MWP).

Motor bearings are grease lubricated and are sized for a minimum of 20,000 hours L10 basic rating life or 100,000 hours median bearing life. Shaft is designed to limit the shaft deflection to no more than .002” at the seal faces. The motor/impeller shaft is protected with a replaceable (bronze/stainless steel) sleeve installed between the shaft and the packing or mechanical seal.

Mechanical seals are designed for water service and light hydrocarbons up to 2500F. Seals are face type with Ni-resist seat, carbon washer, 18-8 stainless steel metal parts and Viton elastomers. Series C pumps are furnished with enclosed dynamically balanced impellers for smooth, low vibration operation.

The impeller is keyed to the shaft for positive driving and is secured in place with a stainless steel washer and self-locking cap screw.

The impeller diameter is no more than 90 percent of the maximum impeller diameter which the case tongue or cut-water could accommodate. This design feature results in low hydraulic noise levels.