Product Description

NewAge Rockmate Portable Hardness Tester

Model MRDR

S/N 1104

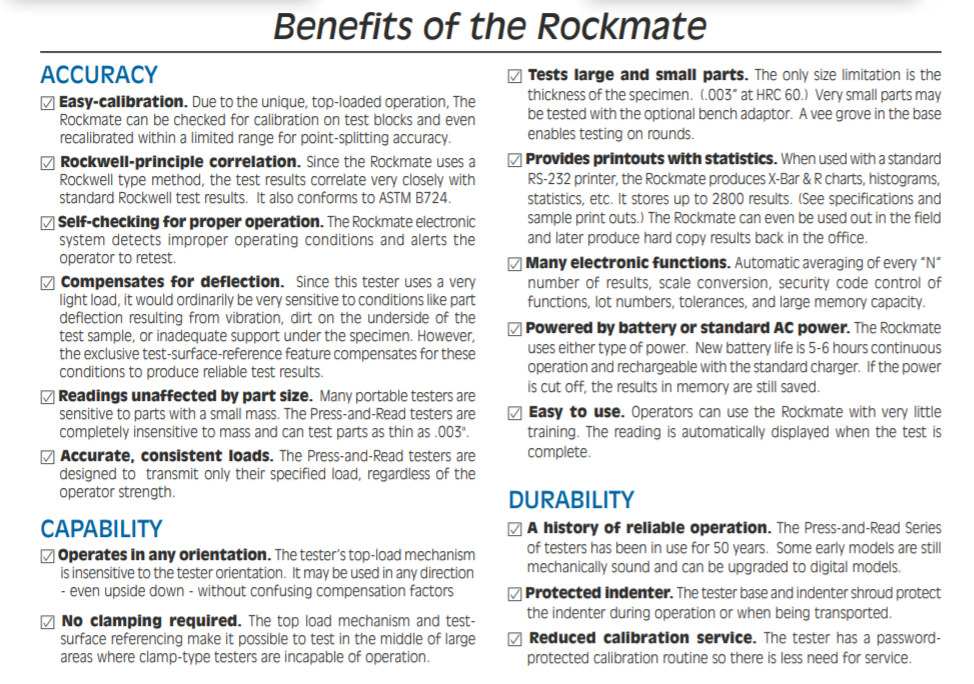

Many thousands of Newage Press-and-Read testers have been sold since their introduction in the early 1950’s. During that time they have proven to be versatile, accurate, and dependable. The newest model, the Rockmate, is the most advanced, light load, portable metal hardness tester made. It can be used to test parts as small as a watch spring, or as large as a huge die block or airplane wing. These testers produce accurate readings even by unskilled operators through the use of a practical test method and a highly sensitive and unique loading system. One smooth motion applies a minor and major load, and measures the test result back to the minor load. Operators cannot overload the tester.

TOP-LOAD, ROCKWELL-PRINCIPLE OPERATION

These testers use a lighter load (approx. 5 kg.) and proportionately smaller indenters than standard Rockwell testers, but the same basic test principle is used (preload, full load, and reading back at pre-load). Also, the Rockmate applies both preload and full load from a single side, so there is no need for a C-clamp design.

NOT AFFECTED BY SHAPE OR SIZE OF PARTS The Rockmate can test on parts with thin walls, or operate upside-down - unlike some other testers.

MEETS ASTM B-724

Rockmate is the only tester that meets this demanding standard for testing aerospace grades of aluminum.

COMPACT SIZE & LIGHT WEIGHT

The MRDR test head measures only 5 1⁄4” tall and has a 1 3⁄4” x 2 1⁄2” base. It weighs only 1 1⁄2 lbs. The electronics can be clipped to the operator’s belt.

PRESS AND READ OPERATION

The entire test is performed by pressing down on the test head, releasing it, and reading the result.

ELECTRONICS

The Rockmate’s advanced electronics provide sophisticated capabilities for statistics, data storage, print out, and custom functions.

READOUTS IN MANY SCALES

All units read in equivalent Rockwell C, B, A, E, Vickers, Brinell HB30, HB5 scales or optional scales .