Product Description

2017 AFC-Holcroft Batch Line

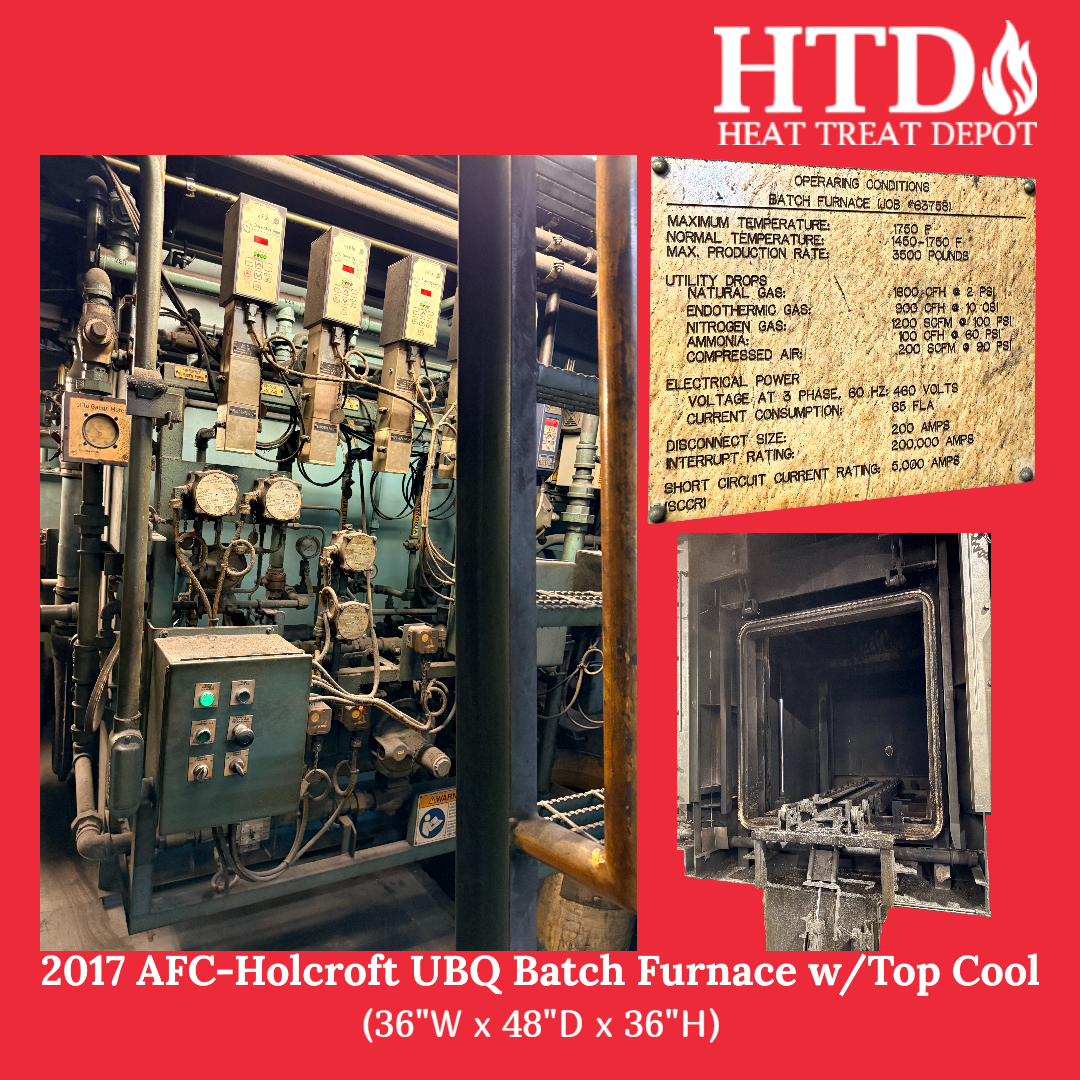

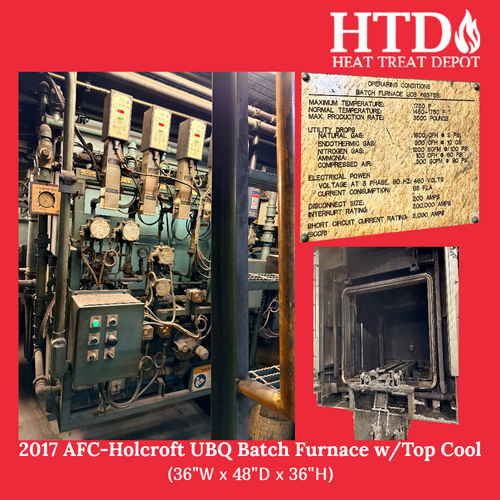

AFC-Holcroft 36x48x36 UBQ Batch Furnace w/Top Cool

Model: UBQ 36-48-36

Serial #: 63758 | Mfg Yr: 2017

Condition: Used in Good shape

UBQ 36-48-36 UNIVERSAL BATCH QUENCH ENGINEERING SPECIFICATIONS

- Effective load size 36” x 48” x 36” (915 mm x 1220 mm x 915 mm)

- Operating range 1450F to 1700F, 1750F maximum (790-930C, 954C maximum)

- Temperature uniformity +/- 10F from set point (+/- 5C from set point)

- Maximum rated load capacity @ 1700F (927C) 3500 pounds | 1600 kg

- Maximum load surface area 400 ft2 |38 m2

- Quench tank capacity 3500 gallons | 13,250 liters

- Maximum quench agitation 16,000 GPM | 60,500 liters/minute

- Ratio of load to quenchant 1 pound to 1 gallon | 0.5 kg to 4 liters

- Maximum recovery rate at 1550F (840C) (load dependent) 2900 pounds/hour |1315 kg/hour

- Maximum recovery rate at 1700F (927C) 2600 pounds/hour | 1180 kg/hour

- Average casing temperature with 1700F (927C) furnace temperature 65F above ambient | 36C above ambient

- Furnace heating chamber size

- 5’-8” wide x 6’-0” long x 5’-6½” high | 1730 mm wide x 1830 mm long x 1690 mm high

- Gas Fired Heating System:

- Number of “U” tubes 4 - 8” diameter | 4 - 200 mm diameter

- Material HT cast alloy

- Mounting concept Bung mounted in roof, external removal

- Heating tube area 88.75 ft2 | 8.25 m2

- Total Btu input 1,200,000 Btu/hr. | 302,400 kcal/hour

- Tube heat dissipation @ 1550F (843C) 60 Btu/in2 net | 0.030 kcal/mm2

- Quench System

- Quench shrouding (% of oil through work) 100%

- Heating- electric Two (2) 9 kW

- Oil Cooler Type Air-to-oil heat exchanger

- Oil cooler capacity 360,000 Btu/hour | 90,720 kcal/hour

(2) AFC-Holcroft 36x48x36 UBT Batch Temper Furnace

Model: UBT 36-48-14G

Serial #: 63788 & 63789 | Mfg Yr: 2017

Condition: Used in Good shape

Effective load size: 36” x 48” x 36” (914 mm x 1219 mm x 914 mm)

- Operating range 300F to 1400F (149-760C)

- Temperature uniformity +/- 10F from set point (+/- 5C from set point)

- Maximum rated load capacity @ 1400F 3500 pounds 1587 kg

- Casing 3/16” PL (4.78 mm)

- PL Door - steel construction with ceramic fiber insulation 6” of ceramic fiber insulation(152 mm of ceramic fiber insulation)

- Hearth (rails and rollers) HH (12 Ni-25 Cr) rails and 3.5” diameter rollers (HH (12 Ni-25 Cr) rails and 88.9 mm diameter rollers)

- Heating System- package burner 850,000 Btu/hr (214,196 kcal/hour)

- Maximum recovery rate at 1400F (760C) 1968 pounds/hour (893 kg/hour)

- Recirculating Fan:

- HP (kW) @ 1750 RPM 7.5 HP (5.59 kW)

- CFM (m3) @ 1006 RPM (6000 CFM 85 m3/minute)

- Furnace Insulation:

- Sidewalls & End walls (Ceramic Fiber Modules) 6” (152 mm)

- Floor (IFB) 7½”(191 mm)

- Roof (Ceramic Fiber Modules)

AFC-Holcroft EZ 4500 Endothermic Generator

Model: EZ 4500

Serial #: 63515 | Mfg Yr: 2017

Condition: Used in Good shape

Retort Material: Centrifugally cast of HU (20/38) alloy

Gas Cooler: Air-cooled heat exchanger

CONTROLLER WITH INTEGRATED TEMPERATURE, DEWPOINT CONTROL AND PRESSURE CONTROL By Super Systems Inc

Standard Features

- Modular design concept allows flexibility to easily add modules

- The casing is lined with 12” (300 mm) thick energy efficient ceramic fiber insulating modules with an average casing temperature of 65F above ambient.

- “Hinged” type combustion chamber door:

- Easy retort removal from hinged door opening

- Eliminates removal of retort from the top

- Eliminates tall clearance height requirements

- Easy accessibility for retort, burner and refractory inspection

- Recuperative type combustion system:

- - Allows for 15% to 25% fuel savings

- - Results in cooler combustion chamber area

- - Reduces heat loss

- Reliable pressure control

- High efficiency air-cooled heat exchanger

- Typical exit gas temperature is 100F (38C) to 160F (71C)

- (depending upon the volume of gas being produced)

- One (1) automatic dew point control system

- Easy retort burn-off system

- NFPA and OSHA compliant

- The casing is constructed of 3/16” and ¼” (5 mm and 6 mm) welded steel plate

- Temperature controlled by an SSi Matrix AutoGen controller and an HMI

- One (1) indicating overtemperature controller

- Two (2) Chromel/alumel thermocouple assemblies complete with protection tube per retort

- One (1) Type K outlet header thermocouple